E-mail: info@plymachine.com WhatsApp:+8619553901259

Views: 35 Author: Site Editor Publish Time: 2024-06-01 Origin: Shandong Jinlun Machinery Manufacturing Co,Ltd

1.Do not wear slippers and high heels during the operation of this equipment. Female employees should pull their hair together. Do not wear vests or shorts

2. Before starting a full inspection to be carried out: The key points for the distribution box, the control cabinet is there any other metal debris, the electrical circuit is missing and the phenomenon of dielectric breakdown, the electrical components and the instrument is intact, the equipment screws are loose Phenomena (especially knives and rotating parts must be checked daily Check), find the problem promptly processed and reported.

3. Equipment requirements Strongly locate and install the grounding wire, the device is strictly prohibited to move, to save power to prohibit the equipment for a long time air operations.

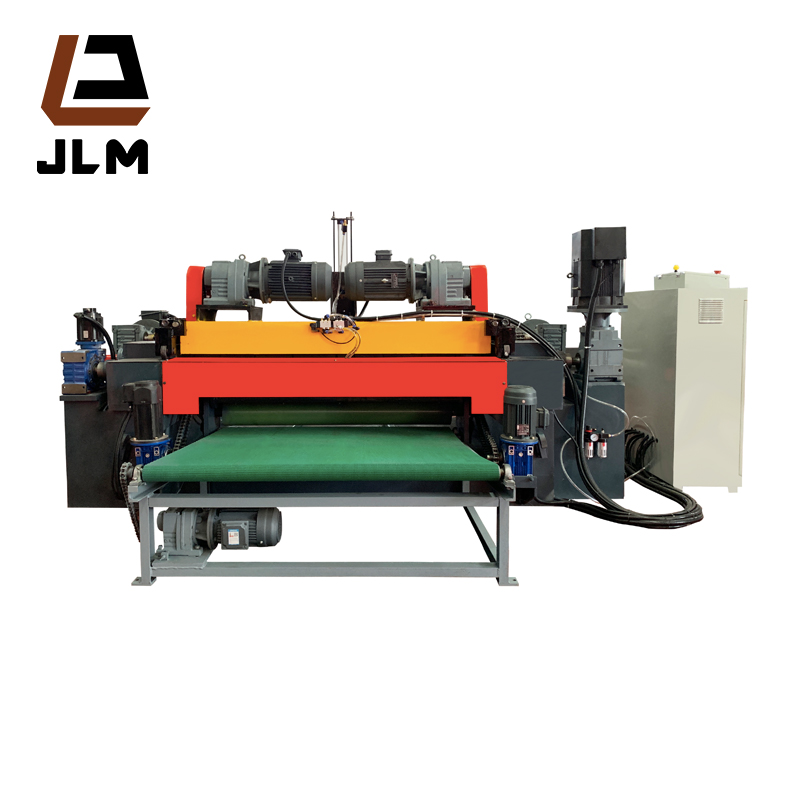

4. Switch wood veneer peeling machine: first check the equipment and confirm the safety of hidden dangers, close the equipment, the main power switch, start and feed the organization began rotary peeling operation. Shutdown; according to the order of the boot stop the control system and then turn off the total power.

5. Equipment maintenance and regular maintenance of the contents of the sliding body (such as: slider, slide), feed screw, chain, bearings, gears and all other sports, rotating contact points to the daily inspection weekly lubricants or Grease care once or twice. The motor is to be serviced secondarily (once every six months) and kept the motor clean and well-ventilated.

6. To protect the equipment to prevent damage to the equipment occurs; wood veneer peeling machine prohibit the placement of other items (especially hard metal items), equipment operation is prohibited manual cleaning of wood chips on the tool.

7. Equipment operators in the removal of peeling after cutting the remaining wooden shaft pay attention to the dynamics of others to suggest that the rotary potentiometer plus, minus cutting speed to be slowly adjusted, can not speed too fast and easy to damage and reduce accuracy, potentiometer Be sure to rotate the zero before shutting down.

8. When replacing the tool or maintenance, be sure to power off and hang up the warning sign. Concentrate on the protective gloves with unexpected protection to ensure unexpected safety before proceeding with the operation. Equipment knife to use special knife grinding machine edge grinding, pay attention to the knife can not burn, keep straight knife edge.

9. Before off work, first disconnect the shunt power and the main control power, and thoroughly clean the equipment, clean the chain, gears, rails and screw debris, debris, etc., so that the equipment is not hidden trouble, do not leave Trouble, always in a safe and good state of operation.