- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

ADDRESS

| Availability: | |

|---|---|

| Quantity: | |

WWXQ130SY-50B

JINLUN

2-13B

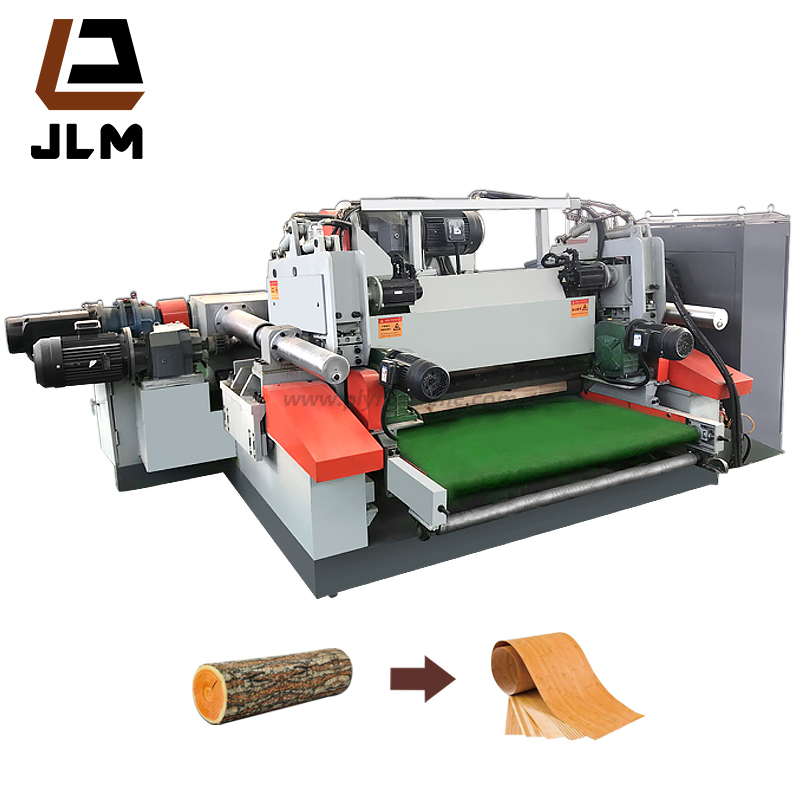

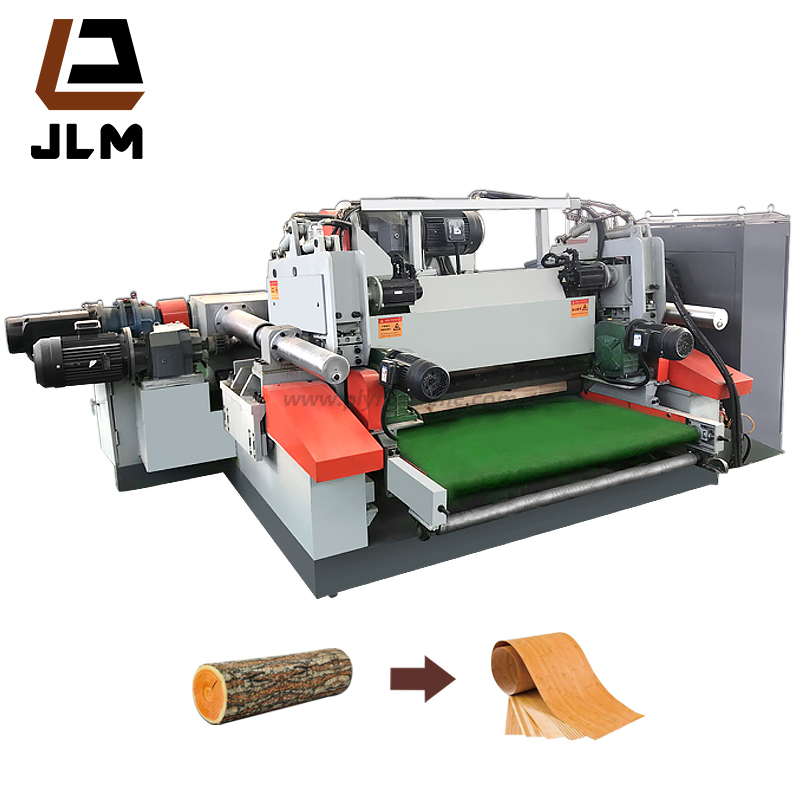

Veneer peeling machine is widely used in wood veneer production line for its important function.

The device is fixed by double-rollers and adopts advanced CNC system, it computes the current diameter of the wood log and the rotational speed of the friction roller.

| MACHINE PARAMETER | |||

| Type | WWXQ150SY-50B | WWXQ260SY-50B | WWXQ320SY-50B |

| Cutting Size (DxL) | Φ500×1500mm | Φ500×2600mm | Φ500×3200mm |

| Min Residual Diameter | Φ28mm | Φ30mm | Φ32mm |

| Max. Diameter | 500mm | 500mm | 500mm |

| Cutting Thickness | 0.5-4.5 mm | 0.5-4.5 mm | 1.0-4.0 mm |

| Cutting Speed | 48-75meters/min | 48-75m/min | 48-75m/min |

| Power | 36kw | 55kw | 65kw |

| Peeling Blade Size | 1500x180x16mm | 2700x180x16mm | 3300x180x16mm |

| Dimensions(LxWxH) | 4600x2150x1560 mm | 5600x2200x1600 mm | 6800x2200x1700 mm |

| Total Weight | 7200kg | 12000kg | 18000kg |

1) New structure---more rational, more sturdy and durable, equal force.

2) New original material---wear resistant,not easy to be out of shape.

3) Famous brand motor----- more powerful, work well for hard wood.

4) Heavy Duty----machine weight is about 7500, heavy enough for any kind of wood and big diameter log.

5) Control system----Adopt New programing, working stable and increase product capacity.

Name: ROLLER

Material : #45

Roller surface is treated by plating chrome and heat, great improve the hardness, strong enough for hard wood, can't crack and deforming,working longer life.

Name: SCREW AND NUT

Material: zinc-base alloy

The screw and nut adopt special alloy material, add

the diameter. not easy to wear, working steady.

Name: SCREW AND NUT

Quantity: 2

screw and guide rail are soaked in oil, reduce the

abrasion and diffuse heating by oil, keep the part

working in high precision. working for a longer life.

Name: GUIDE RAIL TYPE

Shape: V for left and flat for right

Adopt digital lathe guide rail, high precision to keep

veneer thickness tolerance. This structure is our

company patent

1.Easy to operate

2.Reduce investment

3.Easy to maintain

1. save more laborers

2.high product capacity

3.improve the management effectiveness

1. cut log into right size automatically

2.rational conveyor for the complete line

3.save cover area

1. Increase product capacity

2. Reduce investment

3. Easy to operate

Q&A:

1. Q: Are you a factory or a trading company?

A: We are a factory who manufacture the machine by ourself. We have 2 factoies and 1 trading company.

2. Q: What is the delivery time?

A: Normally will be 30 days after getting deposit or original LC.

3. Q: What is the maintenance period? What kinds of after-sale service do you support?

A: 1 year after delivery. We supply telephone after-sale service, video service and e-mail service. If can not deal with the problem, our tech-staff will go abroad to service.

4. Q:What is the payment terms?

A:a.T/T(30% deposit, 70% before delivery in FOB or 70% paied against copy of B/L in CFR)

b. 100% irrevocable L/C at sight.

5. Q: Can we visit your factory?

A: Welcome to visit us! Everyday we have customers from different countries. By now, we have exported to more than 20 countries customer.

Our services:

1.We will send our engineer under your indications to your factory for installing, debugging and maintaining, you only need to afford the cost of the flights, and the engineer's accommodation .

2.If you are experienced in installing jobs, we will provide ongoing technical support for you.

Guarantee time for the main parts of the machine will be 12 months, in this period, if the machines itself have the problem, we will freely maintain it, but not including the problem caused by the wrong or rough operation.

3.The buyer sends people to seller's factory for study:

one month and one person. The buyer should pay for the round air fare, and the seller arrange for food and accommodation, and the service including: the machine's fixing, debugging, operating, maintaining.

4.After the warranty, we can also supply the engineer service and the technical service, but you need to pay the salary for the engineer! and afford the cost of the replaced aparts yourself. More service, you can get by send us an e-mail or a fax.

After Sale service:

Pre-sale services:

1) Provide the free consultation of the equipment

2) Provide the standard device and the flow chart

3) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

4) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Contacts:

We are the manufacturer of plywood machine from China . All of our products are with CE approval and special design according to customer's requirement is available.

More details please contact us .

Veneer peeling machine is widely used in wood veneer production line for its important function.

The device is fixed by double-rollers and adopts advanced CNC system, it computes the current diameter of the wood log and the rotational speed of the friction roller.

| MACHINE PARAMETER | |||

| Type | WWXQ150SY-50B | WWXQ260SY-50B | WWXQ320SY-50B |

| Cutting Size (DxL) | Φ500×1500mm | Φ500×2600mm | Φ500×3200mm |

| Min Residual Diameter | Φ28mm | Φ30mm | Φ32mm |

| Max. Diameter | 500mm | 500mm | 500mm |

| Cutting Thickness | 0.5-4.5 mm | 0.5-4.5 mm | 1.0-4.0 mm |

| Cutting Speed | 48-75meters/min | 48-75m/min | 48-75m/min |

| Power | 36kw | 55kw | 65kw |

| Peeling Blade Size | 1500x180x16mm | 2700x180x16mm | 3300x180x16mm |

| Dimensions(LxWxH) | 4600x2150x1560 mm | 5600x2200x1600 mm | 6800x2200x1700 mm |

| Total Weight | 7200kg | 12000kg | 18000kg |

1) New structure---more rational, more sturdy and durable, equal force.

2) New original material---wear resistant,not easy to be out of shape.

3) Famous brand motor----- more powerful, work well for hard wood.

4) Heavy Duty----machine weight is about 7500, heavy enough for any kind of wood and big diameter log.

5) Control system----Adopt New programing, working stable and increase product capacity.

Name: ROLLER

Material : #45

Roller surface is treated by plating chrome and heat, great improve the hardness, strong enough for hard wood, can't crack and deforming,working longer life.

Name: SCREW AND NUT

Material: zinc-base alloy

The screw and nut adopt special alloy material, add

the diameter. not easy to wear, working steady.

Name: SCREW AND NUT

Quantity: 2

screw and guide rail are soaked in oil, reduce the

abrasion and diffuse heating by oil, keep the part

working in high precision. working for a longer life.

Name: GUIDE RAIL TYPE

Shape: V for left and flat for right

Adopt digital lathe guide rail, high precision to keep

veneer thickness tolerance. This structure is our

company patent

1.Easy to operate

2.Reduce investment

3.Easy to maintain

1. save more laborers

2.high product capacity

3.improve the management effectiveness

1. cut log into right size automatically

2.rational conveyor for the complete line

3.save cover area

1. Increase product capacity

2. Reduce investment

3. Easy to operate

Q&A:

1. Q: Are you a factory or a trading company?

A: We are a factory who manufacture the machine by ourself. We have 2 factoies and 1 trading company.

2. Q: What is the delivery time?

A: Normally will be 30 days after getting deposit or original LC.

3. Q: What is the maintenance period? What kinds of after-sale service do you support?

A: 1 year after delivery. We supply telephone after-sale service, video service and e-mail service. If can not deal with the problem, our tech-staff will go abroad to service.

4. Q:What is the payment terms?

A:a.T/T(30% deposit, 70% before delivery in FOB or 70% paied against copy of B/L in CFR)

b. 100% irrevocable L/C at sight.

5. Q: Can we visit your factory?

A: Welcome to visit us! Everyday we have customers from different countries. By now, we have exported to more than 20 countries customer.

Our services:

1.We will send our engineer under your indications to your factory for installing, debugging and maintaining, you only need to afford the cost of the flights, and the engineer's accommodation .

2.If you are experienced in installing jobs, we will provide ongoing technical support for you.

Guarantee time for the main parts of the machine will be 12 months, in this period, if the machines itself have the problem, we will freely maintain it, but not including the problem caused by the wrong or rough operation.

3.The buyer sends people to seller's factory for study:

one month and one person. The buyer should pay for the round air fare, and the seller arrange for food and accommodation, and the service including: the machine's fixing, debugging, operating, maintaining.

4.After the warranty, we can also supply the engineer service and the technical service, but you need to pay the salary for the engineer! and afford the cost of the replaced aparts yourself. More service, you can get by send us an e-mail or a fax.

After Sale service:

Pre-sale services:

1) Provide the free consultation of the equipment

2) Provide the standard device and the flow chart

3) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

4) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Contacts:

We are the manufacturer of plywood machine from China . All of our products are with CE approval and special design according to customer's requirement is available.

More details please contact us .