- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

ADDRESS

| Availability: | |

|---|---|

| Quantity: | |

CNC venner peeler is important equipment in plywood production line and venner production line.

it main to peeling off small diameter wood and peeling plywood core plate, automatic peeling,

cutting board, fast, provincial labor 2-3 people, Veneer size can be set to change, fully automated

production. For poplar, pine, birch and so on.

PRODUCT SPECIFICATION:

Max length of wood | 1300mm |

Max diameter of wood | 500mm |

Left wood diameter | 28mm |

Veneer peeling thickness | 0.4-3.6 mm |

Size of peeler blade | 1500*180*16mm |

Peeling speed | 60 m/min |

Total Power | 32kw |

weight | 6000KG |

Payment terms | T/T 30%,Balance before loading |

Delivery time | about 25 days after received deposit |

1. Double Roller and single roller

The rollers use 40 hard chrome coating for more

Wearable,Cross the design structure to peeling smaller log

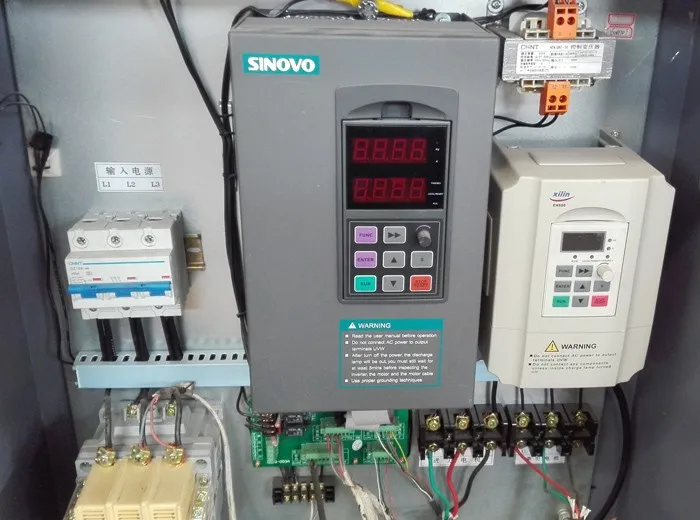

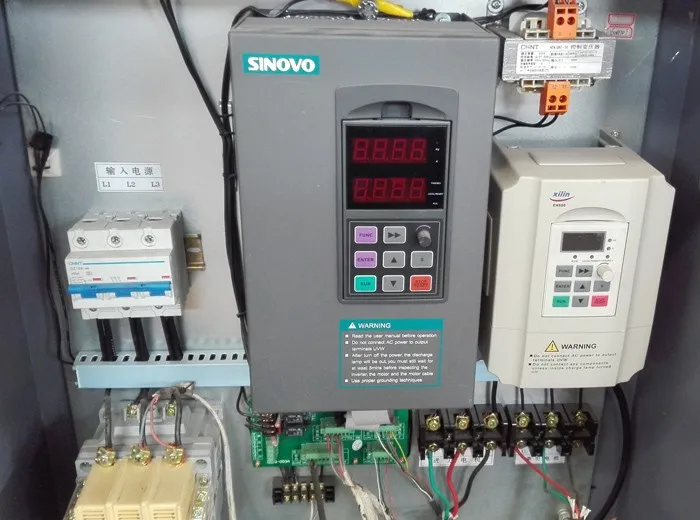

2.PLC control box

Q&A:

1. Q: Are you a factory or a trading company?

A: We are a factory who manufacture the machine by ourself. We have 2 factoies and 1 trading company.

2. Q: What is the delivery time?

A: Normally will be 30 days after getting deposit or original LC.

3. Q: What is the maintenance period? What kinds of after-sale service do you support?

A: 1 year after delivery. We supply telephone after-sale service, video service and e-mail service. If can not deal with the problem, our tech-staff will go abroad to service.

4. Q:What is the payment terms?

A:a.T/T(30% deposit, 70% before delivery in FOB or 70% paied against copy of B/L in CFR)

b. 100% irrevocable L/C at sight.

5. Q: Can we visit your factory?

A: Welcome to visit us! Everyday we have customers from different countries. By now, we have exported to more than 20 countries customer.

Our services:

1.We will send our engineer under your indications to your factory for installing, debugging and maintaining, you only need to afford the cost of the flights, and the engineer's accommodation .

2.If you are experienced in installing jobs, we will provide ongoing technical support for you.

Guarantee time for the main parts of the machine will be 12 months, in this period, if the machines itself have the problem, we will freely maintain it, but not including the problem caused by the wrong or rough operation.

3.The buyer sends people to seller's factory for study:

one month and one person. The buyer should pay for the round air fare, and the seller arrange for food and accommodation, and the service including: the machine's fixing, debugging, operating, maintaining.

4.After the warranty, we can also supply the engineer service and the technical service, but you need to pay the salary for the engineer! and afford the cost of the replaced aparts yourself. More service, you can get by send us an e-mail or a fax.

After Sale service:

Pre-sale services:

1) Provide the free consultation of the equipment

2) Provide the standard device and the flow chart

3) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

4) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Contacts:

We are the manufacturer of plywood machine from China . All of our products are with CE approval and special design according to customer's requirement is available.

More details please contact us .

CNC venner peeler is important equipment in plywood production line and venner production line.

it main to peeling off small diameter wood and peeling plywood core plate, automatic peeling,

cutting board, fast, provincial labor 2-3 people, Veneer size can be set to change, fully automated

production. For poplar, pine, birch and so on.

PRODUCT SPECIFICATION:

Max length of wood | 1300mm |

Max diameter of wood | 500mm |

Left wood diameter | 28mm |

Veneer peeling thickness | 0.4-3.6 mm |

Size of peeler blade | 1500*180*16mm |

Peeling speed | 60 m/min |

Total Power | 32kw |

weight | 6000KG |

Payment terms | T/T 30%,Balance before loading |

Delivery time | about 25 days after received deposit |

1. Double Roller and single roller

The rollers use 40 hard chrome coating for more

Wearable,Cross the design structure to peeling smaller log

2.PLC control box

Q&A:

1. Q: Are you a factory or a trading company?

A: We are a factory who manufacture the machine by ourself. We have 2 factoies and 1 trading company.

2. Q: What is the delivery time?

A: Normally will be 30 days after getting deposit or original LC.

3. Q: What is the maintenance period? What kinds of after-sale service do you support?

A: 1 year after delivery. We supply telephone after-sale service, video service and e-mail service. If can not deal with the problem, our tech-staff will go abroad to service.

4. Q:What is the payment terms?

A:a.T/T(30% deposit, 70% before delivery in FOB or 70% paied against copy of B/L in CFR)

b. 100% irrevocable L/C at sight.

5. Q: Can we visit your factory?

A: Welcome to visit us! Everyday we have customers from different countries. By now, we have exported to more than 20 countries customer.

Our services:

1.We will send our engineer under your indications to your factory for installing, debugging and maintaining, you only need to afford the cost of the flights, and the engineer's accommodation .

2.If you are experienced in installing jobs, we will provide ongoing technical support for you.

Guarantee time for the main parts of the machine will be 12 months, in this period, if the machines itself have the problem, we will freely maintain it, but not including the problem caused by the wrong or rough operation.

3.The buyer sends people to seller's factory for study:

one month and one person. The buyer should pay for the round air fare, and the seller arrange for food and accommodation, and the service including: the machine's fixing, debugging, operating, maintaining.

4.After the warranty, we can also supply the engineer service and the technical service, but you need to pay the salary for the engineer! and afford the cost of the replaced aparts yourself. More service, you can get by send us an e-mail or a fax.

After Sale service:

Pre-sale services:

1) Provide the free consultation of the equipment

2) Provide the standard device and the flow chart

3) According to the clients' special requirement, offering the reasonable plan and free design to help to select the equipment.

4) Welcome to visit our factory

Services during the sales:

1) Inspect the machine before leaving the factory.

2) Oversea install and debug the equipment

3) Train the first-line operator.

After sale services:

1) 24 hours online service

2) Provide the VIDEO with Install and debug the equipment

3) Provide technical exchanging

4) Door to door service is possible

Contacts:

We are the manufacturer of plywood machine from China . All of our products are with CE approval and special design according to customer's requirement is available.

More details please contact us .