E-mail: info@plymachine.com WhatsApp:+8619553901259

Views: 0 Author: Site Editor Publish Time: 2025-08-29 Origin: Site

Poor integration of a log debarker into the production line can create bottlenecks, increase material handling, and cause equipment damage, ultimately reducing overall efficiency. This practical guide explains how to effectively fit a hydraulic log debarker into your plywood production workflow to optimize material flow, reduce manual intervention, and improve line balance.

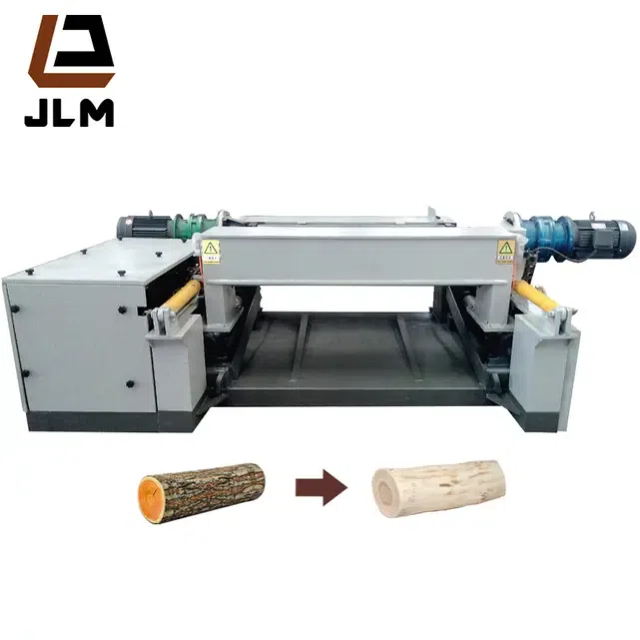

A log debarker is a critical machine positioned early in the veneer production line. Its primary function is to remove bark and round logs before they reach the veneer peeling machine. Ideally, the debarker should be located immediately after the log yard and any primary log sorting or sizing equipment.

The typical workflow starts with logs transported from storage or harvest sites to the debarker. After debarking, logs are fed directly into peeling lathes where thin veneer sheets are produced. Downstream from peeling, veneer goes through drying, grading, and panel assembly processes.

Correct positioning ensures that logs enter the peeling machine clean and uniformly shaped, protecting peeling knives and improving veneer quality. Integrating the debarker seamlessly in this flow minimizes material handling steps, cutting labor costs and reducing damage risks.

In addition, a well-integrated workflow allows for better monitoring and control of log quality at earlier stages. For example, if the debarker is placed close to sorting stations, it’s easier to reject unsuitable logs before debarking, preventing costly processing of defective material.

Strategic placement of the log debarker in relation to upstream and downstream equipment is essential. The machine should have easy access to feed conveyors from the log yard, allowing smooth, mechanized log transfer onto the debarker.

Using hydraulically powered feed rollers or chain conveyors can automate log movement into the debarker, reducing or eliminating the need for manual repositioning. Automated reject systems or adjustable guides can help remove oversized or defective logs before processing, protecting the debarker and peeling machines.

After debarking, logs should exit directly onto conveyors aligned with peeling machines. Minimizing log transfer distances and the number of manual handling points reduces damage risk and speeds up production cycles.

Properly designed conveyor layouts also improve workplace safety by limiting the need for operators to manually handle heavy logs or intervene between machines. Additionally, incorporating sensors and automation on conveyors can help detect jams or misfeeds early, allowing for faster intervention and reducing downtime.

A key consideration in conveyor design is ensuring that the speed and angle of conveyors are compatible with the log dimensions and the debarker’s output speed. Too steep or fast conveyors can cause logs to bounce or become misaligned, potentially damaging the logs or equipment.

Factories should also consider space constraints and future expansion plans when designing conveyor routes. Flexible conveyor modules that can be adjusted or extended allow easier line reconfiguration as production demands change.

Effective synchronization between the log debarker and veneer peeling machines is key to maintaining continuous production and avoiding bottlenecks.

The debarker’s feed rate should match the peeling line’s processing speed. Automated control systems can monitor peeling machine status and dynamically adjust debarker speed and pressure settings to maintain smooth log supply.

Buffer zones or intermediate conveyors between the debarker and peelers help absorb speed fluctuations and allow short-term storage to prevent starvations or backups. These zones can be equipped with sensors to monitor log accumulation and automatically regulate feed rates.

Additionally, communication protocols between machines, such as programmable logic controllers (PLCs), enable real-time coordination, ensuring the entire line runs harmoniously. This synchronization improves throughput and maximizes equipment utilization.

Proper synchronization not only boosts efficiency but also prolongs machine lifespan by avoiding sudden surges or idle times, which can stress mechanical components. Well-coordinated lines also allow operators to better plan maintenance windows without disrupting production flow.

Furthermore, factories might implement centralized monitoring systems where operators can view the status of the entire production line, from log yard to finishing. This visibility aids quick troubleshooting and proactive management of workflow.

Reliable operation depends on disciplined maintenance and safety practices.

Daily maintenance should include checking hydraulic fluid levels, inspecting feed rollers and claws for wear, and clearing bark debris from conveyors and extraction points. Weekly tasks might involve lubricating moving parts, tightening bolts, and testing emergency stop functions.

Establishing a clear spare-parts inventory for wear liners, hydraulic seals, and feed rollers minimizes downtime caused by part failures. Partnering with suppliers who provide quick delivery and technical support ensures the debarker remains operational.

Safety protocols should enforce lockout/tagout procedures during maintenance, operator training on machine controls, and clear signage around hazardous areas.

Beyond scheduled maintenance, encouraging operators to report unusual noises, vibrations, or changes in performance early can prevent minor issues from becoming costly breakdowns.

Implementing a digital maintenance log system can help track maintenance activities, part replacements, and machine condition over time, allowing predictive maintenance and reducing unexpected failures.

Tracking key performance indicators (KPIs) is essential for measuring integration success:

Uptime: Percentage of scheduled operating time when the debarker is fully functional. Higher uptime correlates with fewer disruptions.

Cycle time: Average time to process one log through debarking and feed it into peeling. Shorter cycle times indicate efficient flow.

Reject rate: Percentage of logs or veneer affected by debarking issues causing defects. A low reject rate reflects good debarking quality and integration.

Regular KPI monitoring allows early detection of bottlenecks or maintenance needs, facilitating timely corrective actions and continuous improvement.

Including operator feedback and maintenance logs can complement KPI data, offering a more comprehensive picture of integration effectiveness.

Periodic review meetings involving production, maintenance, and quality teams ensure KPIs align with operational goals and help identify improvement opportunities.

Successfully integrating a log debarker into your plywood factory workflow requires a clear understanding of current material flow, careful placement and conveyor design, synchronization with peeling lines, and rigorous maintenance planning.

Start by mapping your existing production flow, then simulate optimal debarker placement using layout software or physical mock-ups. Conduct a pilot integration to collect performance data and refine processes based on KPIs.

Shandong Jinlun Machinery Manufacture Limited Company provides hydraulic log debarker solutions designed for easy integration into modern veneer production lines. For tailored integration support and product advice, please contact us and let us help you optimize your plywood factory workflow.