E-mail: info@plymachine.com WhatsApp:+8619553901259

Views: 0 Author: Site Editor Publish Time: 2025-09-25 Origin: Site

Investing in a wood debarker machine is a crucial decision for wood processing operations in 2025. With the demand for high-quality timber products increasing and labor costs rising, mechanized debarking has become essential. These machines remove bark efficiently, save labor, improve product consistency, and enhance operational safety compared to manual methods. Prices vary widely based on machine type, capacity, and features, making cost analysis essential for budgeting and return on investment (ROI).

Understanding wood debarker machine pricing and its impact on production efficiency can guide businesses toward optimal decisions. Whether you operate a small workshop or a large sawmill, selecting the right machine ensures faster throughput, consistent quality, and minimal wood waste. This article provides a detailed overview of wood debarker machine cost analysis, pricing factors, key features, and guidance for selecting the right equipment.

A wood debarker machine is designed to remove bark from logs automatically, providing a cleaner and smoother surface for downstream processing. Unlike manual methods, which are slow and inconsistent, these machines offer high-speed debarking and uniform results. Various types exist, including drum debarkers, ring type machines, chain systems, and portable tools. Each type has its own advantages based on log size, bark type, and production needs.

Debarking enhances wood quality by preventing defects caused by remaining bark. Bark can lead to discoloration, uneven texture, and chemical contamination during pulp production. In addition, clean logs reduce wear and tear on saw blades and other milling equipment, extending tool life and lowering maintenance costs. Modern machines also include adjustable speed, pressure, and blade settings to accommodate different wood species, ensuring minimal damage and high efficiency.

Manual debarking is labor-intensive and slow, requiring significant effort and time. A wood debarker machine accelerates the process, processing hundreds of logs per hour depending on capacity. High-throughput machines are ideal for pulp mills and large sawmills, where productivity is critical. Automated systems reduce labor costs, improve safety, and allow workers to focus on other value-added tasks. High-speed debarking also minimizes bottlenecks in the production line, ensuring continuous operation and consistent supply for downstream processes.

Consistency is vital for wood quality. Manual debarking often leaves uneven patches, causing issues during milling or finishing. Using a wood debarker machine ensures uniform bark removal across all logs, which is essential for furniture, veneer, and specialty wood production. Adjustable machines allow operators to fine-tune settings for different wood types, log diameters, and bark thicknesses, resulting in minimal defects and improved product value.

Bark left on logs can cause wood defects, chemical contamination, or processing difficulties. A wood debarker machine removes bark thoroughly, reducing waste and improving finished product quality. Clean logs also reduce the need for additional sanding or chemical treatments, saving time and materials. High-quality debarking ensures better adhesion of finishes, more consistent drying, and fewer imperfections, which is especially important for premium wood products like furniture or specialty lumber.

Modern wood debarker machines use different mechanisms for bark removal:

● Drum Debarkers: Logs rotate inside a drum against abrasive surfaces. Ideal for high-volume pulp production.

● Ring Type Debarker Machine: Logs pass through a rotating ring that removes bark. Suitable for medium-to-large sawmills.

● Chain Log Debarker System: Uses chains to scrape bark from rough or hardwood logs. Efficient for varied log sizes.

● Portable Tree Debarker Tool: Lightweight and mobile, perfect for small-scale or mobile operations.

Each mechanism has advantages depending on log type, production volume, and wood species. For example, drum debarkers are more efficient for softwoods and uniform logs, while chain debarkers handle hard, rough-barked logs better.

Most machines offer adjustable speed, pressure, and blade settings. This allows operators to handle different wood types, log diameters, and bark thicknesses without damaging the wood. Some models feature modular drums, interchangeable blades, or programmable sequences. Proper adjustments enhance efficiency, reduce downtime, and extend machine lifespan.

提示: Choose machines with easy-to-adjust settings and quick blade replacement to minimize downtime.

Sawmills play a critical role in converting raw logs into lumber and boards. For these operations, using a ring type debarker machine is essential to prepare logs for cutting. Clean, bark-free logs not only protect expensive saw blades from premature wear but also ensure uniform board thickness and surface quality. High-volume sawmills often operate multiple lines simultaneously, and any inconsistency in debarking can create bottlenecks that slow down the entire production process. Ring type debarkers excel in this environment because they can handle medium-to-large logs continuously, removing bark efficiently without causing wood damage. Additionally, adjustable settings allow operators to accommodate logs of different diameters and bark thicknesses, further improving throughput and reducing downtime. The result is a more reliable production line, reduced maintenance costs, and higher-quality finished products that meet stringent market standards.

In pulp and paper mills, the quality of raw fiber directly affects the final product’s brightness, strength, and texture. Drum debarkers are particularly suited for this industry because they can process high volumes of logs with varying diameters and species efficiently. Bark and dirt left on logs can introduce impurities into the pulp, leading to reduced fiber quality and increased chemical consumption during bleaching and processing. By removing bark thoroughly, drum debarkers improve pulp uniformity and reduce waste, which in turn lowers operational costs. Many modern pulp mills integrate drum debarkers into automated log handling systems, allowing continuous feeding and processing without human intervention. This not only increases throughput but also ensures consistent fiber quality for paper and board production. Furthermore, proper debarking reduces wear on downstream machinery such as chippers and refiners, extending equipment life and reducing maintenance intervals.

Fine woodworking and specialty lumber production demand defect-free logs to create high-end furniture, flooring, and veneers. A chain log debarker system is ideal in these contexts because it provides precise and even bark removal, leaving the wood surface smooth and intact. Imperfections caused by residual bark can lead to discoloration, uneven staining, and compromised adhesion of finishes, which are critical in premium products. Chain debarkers also allow operators to handle hardwoods and rough-barked species more effectively than other debarking methods. Many furniture manufacturers integrate these machines into small-scale production lines, where careful handling of each log is essential. Additionally, the ability to adjust pressure and speed ensures that delicate species are not damaged during debarking, preserving both aesthetic and structural integrity. By using high-quality debarking systems, furniture makers and specialty wood producers can minimize waste, reduce sanding and rework, and deliver products that meet stringent design and quality expectations.

For farmers, small workshops, or rural operations, a portable tree debarker tool offers a practical and cost-effective solution. These lightweight, manually operated or small motorized tools are designed for occasional use, such as preparing firewood, fencing, or small-scale lumber projects. Portable debarkers allow operators to remove bark efficiently without investing in large industrial machines, which may be unnecessary for low-volume applications. Despite their smaller size, these tools often feature adjustable settings for different log diameters, ensuring clean bark removal while minimizing wood damage. Their portability also allows use directly at the worksite, eliminating the need to transport heavy logs to a central facility. Additionally, portable debarkers are easy to maintain and repair, with replacement parts readily available, making them ideal for rural or mobile applications where resources may be limited.

Selecting the right wood debarker machine starts with understanding your production volume. Large-scale operations, such as industrial sawmills or pulp mills, require high-capacity industrial debarkers capable of processing hundreds of logs per hour. These machines are designed for continuous operation, minimizing downtime and ensuring consistent debarking quality across large batches. In contrast, small producers, hobbyists, or mobile workshops benefit from portable or semi-automatic machines. These tools are easier to transport, cost-effective, and sufficient for low-volume projects like fencing, firewood preparation, or occasional lumber processing. Choosing the wrong scale can lead to significant inefficiencies: an oversized machine may result in unnecessary energy consumption and high initial costs, while an undersized unit could create bottlenecks, slowing down production and increasing labor expenses. Therefore, it’s crucial to evaluate not only current production needs but also potential fluctuations in workload. Factors such as seasonal demand, project variety, and anticipated business growth should guide the choice, ensuring that the machine aligns with operational requirements while remaining economically viable.

Another critical factor when selecting a wood debarker machine is the type of wood being processed. Different species have varying bark thickness, hardness, and texture. For instance, hardwoods like oak or hickory often have thick, rough bark that can be difficult to remove, making a chain log debarker system more suitable. Chains can grip and strip bark effectively without damaging the wood underneath. Softwoods such as pine or fir, which often have smoother bark, are better suited to ring type or drum debarkers. These machines rotate logs against abrasive surfaces or rotating rings, efficiently removing bark while preserving wood integrity. Matching the debarking mechanism to the wood type ensures maximum efficiency, prevents machine strain, and reduces the risk of surface defects. Additionally, some advanced machines offer adjustable pressure, speed, and feed settings to handle mixed-species batches, which is particularly useful for operations processing multiple wood types. By carefully considering the wood species and bark characteristics, operators can optimize machine performance, extend equipment life, and improve the quality of the debarked logs for downstream processing.

Budget considerations are central to selecting the right wood debarker machine. Industrial drum debarkers and large ring-type machines typically require significant upfront investment but deliver fast ROI through high throughput, reduced labor costs, and minimized downtime. For businesses with high production demands, the efficiency gains quickly offset initial costs. Conversely, portable debarkers or smaller units are more affordable initially but may have lower throughput, limiting their effectiveness in high-volume operations. When evaluating budget, it’s important to consider not just purchase cost but long-term savings, including energy efficiency, reduced labor, lower maintenance, and potential downtime. Conducting a detailed wood debarker machine cost analysis or price comparison between models can provide clarity on the total cost of ownership. Many companies also calculate ROI based on the number of logs processed per hour, helping determine how quickly the investment will pay off. A well-chosen debarker balances upfront cost against operational efficiency, scalability, and product quality to ensure that the machine contributes positively to the bottom line over its lifetime.

The ongoing maintenance of a wood debarker machine significantly affects productivity and total cost of ownership. Machines that allow easy replacement of chains, blades, or drums reduce downtime and simplify routine maintenance. Industrial debarkers often include automated lubrication systems, quick-release components, and accessible service points to streamline upkeep. Regular maintenance schedules, including checking bearings, tightening feed mechanisms, and inspecting cutting elements, help prevent breakdowns and extend machine lifespan. Neglecting maintenance can lead to decreased debarking quality, higher energy consumption, and costly repairs. Additionally, operators should consider the availability of replacement parts and technical support when choosing a machine. For smaller portable units, maintenance is generally simpler, but even these machines require periodic inspection to ensure blades remain sharp and motors function correctly. Factoring in both labor and parts costs when assessing wood debarker machine pricing ensures an accurate understanding of total operating expenses.

Investing in a wood debarker machine is not just about current needs—it’s also about future growth. Industrial debarkers often provide scalability options, such as modular feed systems, higher-capacity drums, or adjustable speed settings, allowing the machine to accommodate increased production volumes. For growing businesses, selecting a scalable machine prevents the need for immediate replacement as demand rises, offering long-term operational flexibility. Portable units, while convenient for small-scale tasks, may not meet future capacity requirements and could require additional investments if production expands. Business owners should assess anticipated growth, project pipeline, and potential expansion plans when choosing a debarker. Machines that can adapt to higher loads, different wood species, or mixed-size logs ensure a future-proof investment that maintains efficiency, quality, and profitability. By prioritizing scalability, operators can confidently plan for long-term growth without compromising production or incurring unnecessary costs.

Tip: Consider modular and upgradable debarker options to accommodate future production increases and ensure long-term value.

Machine Type | Price Range (USD) | Suitable Production Scale |

Drum Debarker | 40,000 – 120,000 | High-volume pulp mills |

Ring Type Debarker | 35,000 – 90,000 | Medium-large sawmills |

Chain Debarker | 25,000 – 70,000 | Hardwood logs, specialty wood |

Portable Debarker | 1,500 – 5,000 | Small-scale or mobile projects |

Costs vary depending on capacity, automation level, adjustability, and brand. Factoring in maintenance, energy, and labor savings provides a clearer picture of total cost of ownership.

Tip: Compare suppliers and machine capabilities before purchase to ensure cost-effectiveness.

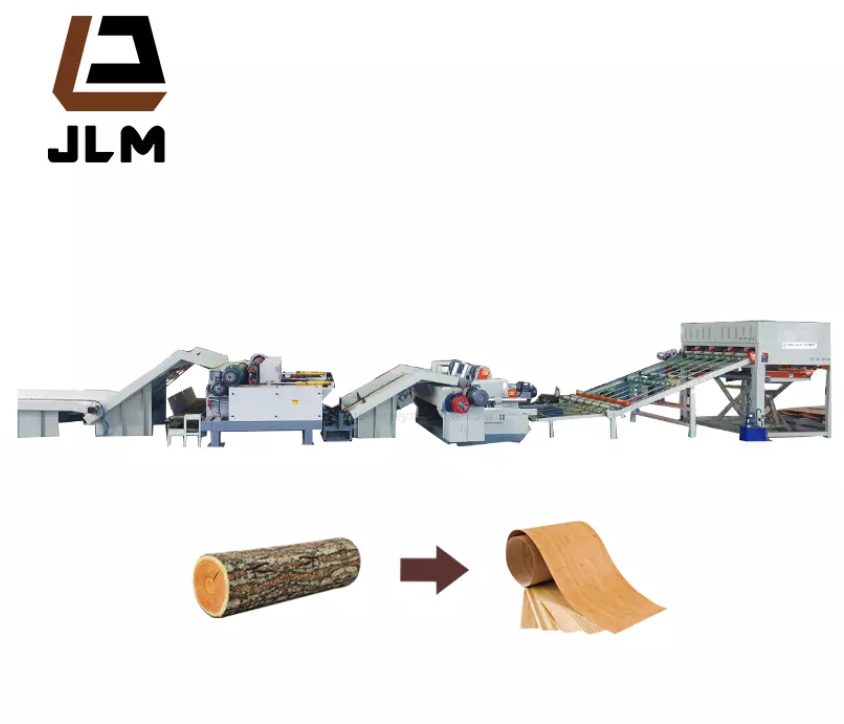

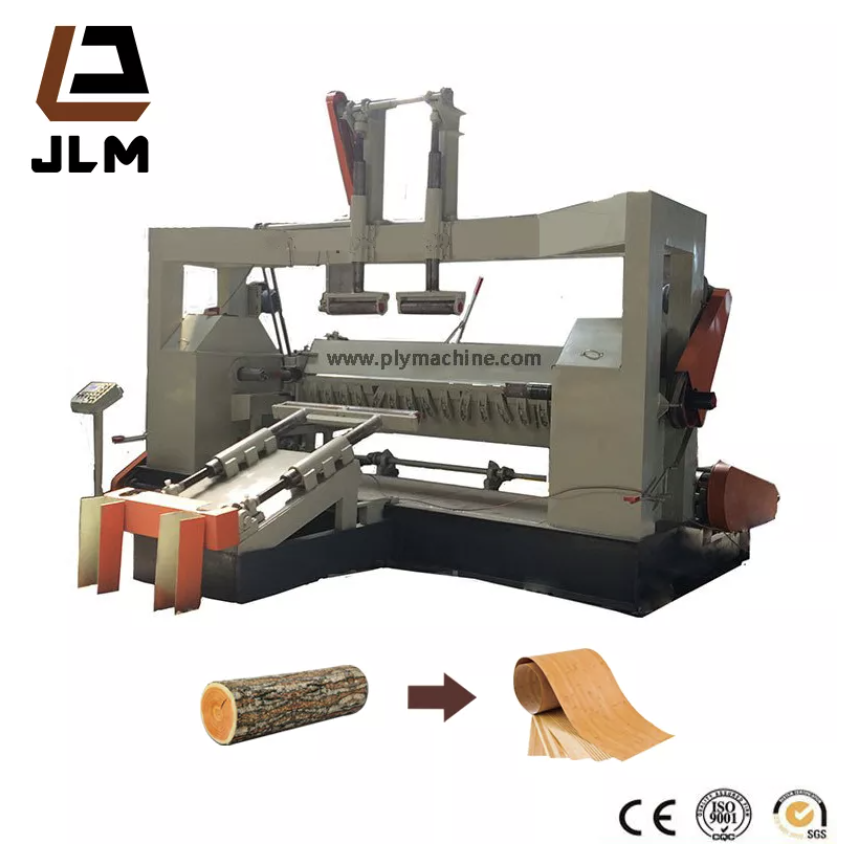

Discover our wood debarker machines to enhance efficiency and product quality. Different models suit various production scales and wood types.

Visit Shandong Jinlun Machinery manufacture limited company for reliable machines with advanced features. Their solutions help businesses save time, reduce waste, and achieve higher ROI. Choosing the right model ensures long-term value and operational success.

A: A wood debarker machine removes bark from logs efficiently, improving wood quality.

A: Prices vary; wood debarker machine pricing depends on size, type, and production capacity.

A: It increases efficiency, reduces labor, and ensures uniform wood for various applications.

A: Factors include machine type, production volume, maintenance, and material specifications.

A: Conduct a wood debarker machine price comparison considering features, throughput, and ROI.

A: Yes, portable and smaller wood debarker machines suit small workshops or occasional use.