E-mail: info@plymachine.com WhatsApp:+8619553901259

Views: 0 Author: Site Editor Publish Time: 2025-09-25 Origin: Site

Ever wondered how logs become smooth and ready for production? A debarker machine removes bark efficiently and quickly.

In this article, we explore different types of debarker machines. You will understand their uses, benefits, and applications.

By reading this guide, you’ll learn how to choose the right debarker machine for your wood processing needs.

A debarker machine is specialized equipment designed to remove bark from logs efficiently. Bark removal is critical for sawmills, pulp mills, and furniture manufacturing. Bark left on logs can harbor dirt, fungi, or insects, reducing wood quality and causing defects in processed boards. Debarking also protects cutting tools, reduces maintenance costs, and ensures uniform board dimensions.

Modern debarker machines handle various log sizes and wood species, ranging from softwoods to hardwoods. They can operate in high-volume industrial environments or as portable tools for small-scale projects. The key purpose is to produce clean, smooth logs ready for further processing while minimizing labor and maximizing operational efficiency.

Debarker machines vary based on the mechanism used to remove bark. Common types include:

● Drum Log Debarkers: Logs rotate against abrasive surfaces, efficiently peeling bark in high-volume operations.

● Ring Type Debarkers: A rotating ring adapts to logs of uneven bark thickness, ensuring consistent debarking.

● Chain Log Debarker Systems: Chains or conveyor belts scrape bark from rough or irregular logs.

● Portable Debarker Tools: Lightweight and cost-effective, ideal for small workshops, firewood preparation, or fencing projects.

Selecting the appropriate type depends on production volume, log characteristics, and operational requirements.

提示: Assess both log type and production scale before purchasing a debarker machine to avoid inefficiency.

Manual debarking is labor-intensive and slow. Industrial debarker machines automate the process, significantly reducing processing time. High-volume sawmills and pulp mills benefit from continuous debarking, which eliminates bottlenecks and improves throughput. Faster debarking also reduces labor costs and allows operators to focus on other value-added tasks.

Debarker machines provide uniform bark removal, reducing wood defects and ensuring smooth surfaces. Machines like drum and ring type debarkers maintain consistent results across logs of different sizes and species. Consistency is particularly important in sawmills producing standardized boards and pulp mills requiring uniform fiber quality.

Debarked logs improve product quality and reduce material waste. Bark can cause surface discoloration, uneven texture, and impurities in wood products. Using tree debarking equipment ensures logs are clean, minimizing defects and improving the aesthetics of finished products. Cleaner logs also require less chemical treatment in pulp processing, contributing to cost savings and environmental benefits.

注释: Investing in a debarker machine enhances product quality, operational efficiency, and long-term ROI.

Debarker machines feature several mechanisms designed to match different operational needs:

Debarker Type | Mechanism | Ideal Usage | Advantages |

Drum Log Debarker | Rotating drum | High-volume sawmills, pulp mills | Fast, handles mixed log sizes |

Ring Type Debarker | Rotating ring | Smooth or uneven bark logs | Consistent removal, adaptable |

Chain Log Debarker | Chain scraper | Rough bark, irregular logs | Gentle on wood, precise |

Portable Debarker Tool | Manual/portable motor | Small workshops, farms | Lightweight, flexible, low-cost |

Each mechanism has advantages depending on log type, production volume, and operational goals.

Modern machines allow speed, pressure, and precision adjustments. This is critical for handling diverse wood species and varying bark thicknesses. Adjustable machines prevent wood damage and optimize bark removal efficiency. Operators can set parameters for different production runs, ensuring consistent quality across logs.

Debarker machines include safety shields, emergency stops, and replaceable chains or blades. Regular maintenance prolongs lifespan and reduces downtime. Efficient maintenance practices ensure continuous operation, particularly in industrial applications with high production demand.

提示: Confirm maintenance ease and safety compliance when selecting a debarker machine.

In sawmill operations, a ring type debarker machine prepares logs for cutting, reducing blade wear and producing uniform boards. High-volume sawmills rely on continuous debarking to maintain efficiency and prevent production delays. Proper debarking reduces secondary sanding and improves overall product quality. Ring debarkers adapt to logs of varying diameters and bark thickness, ensuring even bark removal and protecting downstream equipment. Logs that are debarked efficiently also dry more predictably, reducing warping and enhancing lumber stability.

Integrating an industrial debarker machine into the sawmill line allows for seamless operation, where logs are automatically processed before entering saws or chippers. This reduces manual labor, improves throughput, and ensures consistent output. Properly debarked logs require less finishing, saving time and cost while producing higher-value lumber for construction, flooring, and furniture.

In pulp and paper mills, drum log debarkers are essential for handling high volumes of mixed log sizes. Removing bark before pulping improves fiber quality, increases pulp brightness, and reduces chemical usage. Bark contains dirt and extractives that can negatively affect chemical pulping processes and bleaching efficiency.

Efficient debarking also decreases mechanical wear on chippers and digesters, extending equipment life and reducing downtime. Mills that integrate industrial debarker machines achieve higher throughput and consistent fiber quality, critical for large-scale production. Clean logs support energy efficiency, minimize waste, and help meet environmental and sustainability goals.

For fine woodworking and high-end furniture production, a chain log debarker system ensures smooth, defect-free surfaces. Proper debarking prevents imperfections that compromise aesthetics or structural integrity. Chain debarkers remove bark without damaging the wood, which is crucial for hardwoods and softwoods used in cabinetry, flooring, and veneers.

Adjustable settings allow operators to handle different log sizes and species, making chain debarkers suitable for small-batch or specialty production. Accurate debarking reduces the need for sanding and finishing, saving labor costs while maintaining premium quality.

Portable debarker tools are ideal for small workshops, farms, or occasional users. Lightweight and cost-effective, they simplify firewood preparation, fencing projects, and small-scale lumber production. These machines reduce labor compared to manual peeling and can handle logs of varying sizes efficiently.

Portable debarkers offer flexibility for mobile operations, allowing users to debark logs onsite and minimize transport weight. While smaller than industrial machines, they provide sufficient efficiency for low-volume projects and occasional use.

When selecting a debarker machine, production volume is the primary consideration. Industrial operations that process hundreds or thousands of logs per day require industrial debarker machines capable of continuous, high-volume debarking. These machines are designed to operate 24/7, maintain consistent output, and reduce labor dependency. Using a portable or small-scale machine in such a setting would create bottlenecks, slow production, and reduce overall efficiency.

Conversely, small producers, farmers, or specialty woodworkers often require portable debarker tools or low-capacity machines. These tools are lightweight, easy to transport, and suitable for intermittent use. Choosing a machine that exceeds your production needs leads to underutilized capacity and wasted capital investment, while undersized equipment slows workflow. Aligning the machine scale with actual output needs ensures operational efficiency and improves the return on investment over time.

Different types of wood present unique challenges for debarking. Softwoods, like pine or spruce, often have thin, loosely attached bark, whereas hardwoods, such as oak or maple, feature thicker, more fibrous bark. Selecting the appropriate debarker machine depends on bark texture and thickness.

Chain debarkers are ideal for rough or uneven bark because their chain-driven scraping mechanisms provide aggressive yet controlled bark removal. Ring type debarker machines perform better on smooth, uniform logs, delivering even results without damaging the wood. Matching the debarking mechanism to the wood type improves efficiency, minimizes waste, and prevents unnecessary wear on the machine. Failure to consider wood species can lead to incomplete bark removal, excessive machine strain, and increased maintenance costs over time.

Cost is a critical factor when choosing a debarker machine, but the focus should be on long-term value rather than upfront purchase price. Drum log debarkers generally have higher initial costs due to their robust construction and high throughput. However, these machines deliver rapid ROI by reducing labor, improving production efficiency, and lowering waste.

For low-volume operations, portable debarker tools offer a budget-friendly alternative. While these machines have limited capacity, they provide flexibility and low initial investment. Evaluating total cost of ownership is essential. Consider labor savings, maintenance requirements, energy consumption, and the machine’s lifespan. Calculating cost per processed log or per cubic meter of wood ensures a more accurate assessment of long-term financial benefits and prevents overspending on unnecessary capacity.

Efficient operation depends not only on the machine’s design but also on ongoing maintenance. Machines equipped with quick-change chains, blades, or rollers significantly reduce downtime, allowing operations to continue with minimal interruption. Regular inspections, lubrication, and blade sharpening keep the debarker machine performing optimally and prevent costly breakdowns.

Effective debarking also protects downstream equipment. Logs that are fully debarked reduce wear on saw blades, chippers, and other processing machines, minimizing replacement costs and extending the lifespan of the entire production line. Planning maintenance schedules and ensuring operators are trained in proper machine handling maximizes both productivity and durability, making the investment in a high-quality machine worthwhile over its service life.

Businesses should consider future growth when choosing a debarker machine. Industrial-scale machines offer scalability, handling increased log volumes as production expands. Investing in modular or upgradeable equipment allows businesses to add capacity without replacing the entire machine.

Portable debarker tools, while ideal for small-scale or intermittent production, have limited scalability. However, they remain valuable for niche applications or for operations testing new markets. Selecting a machine that aligns with both current needs and future expansion ensures long-term operational flexibility and maximizes ROI. Forward-looking planning prevents the costly scenario of outgrowing a machine prematurely and supports sustainable growth.

提示: Evaluate long-term efficiency by calculating the cost per processed log rather than focusing solely on initial purchase price. This approach helps compare different machines fairly and ensures smarter investment decisions.

Understanding wood debarker machine pricing is essential for informed purchasing decisions. Costs vary based on type, size, and production capacity. Industrial drum debarkers typically range higher due to automation, durability, and throughput capabilities. Ring type debarkers may have moderate pricing while offering versatility. Portable tools are the most cost-effective, ideal for low-volume operations.

Additional factors impacting cost include installation, maintenance, labor, and energy consumption. A complete wood debarker machine cost analysis should consider total operational expenses, not just the purchase price. Comparing wood debarker machine price comparison charts can help businesses identify options that balance cost with performance. Cost estimation tools provide insights into ROI, payback periods, and scalability potential.

提示: Include installation and operational costs in your budgeting for realistic ROI assessment.

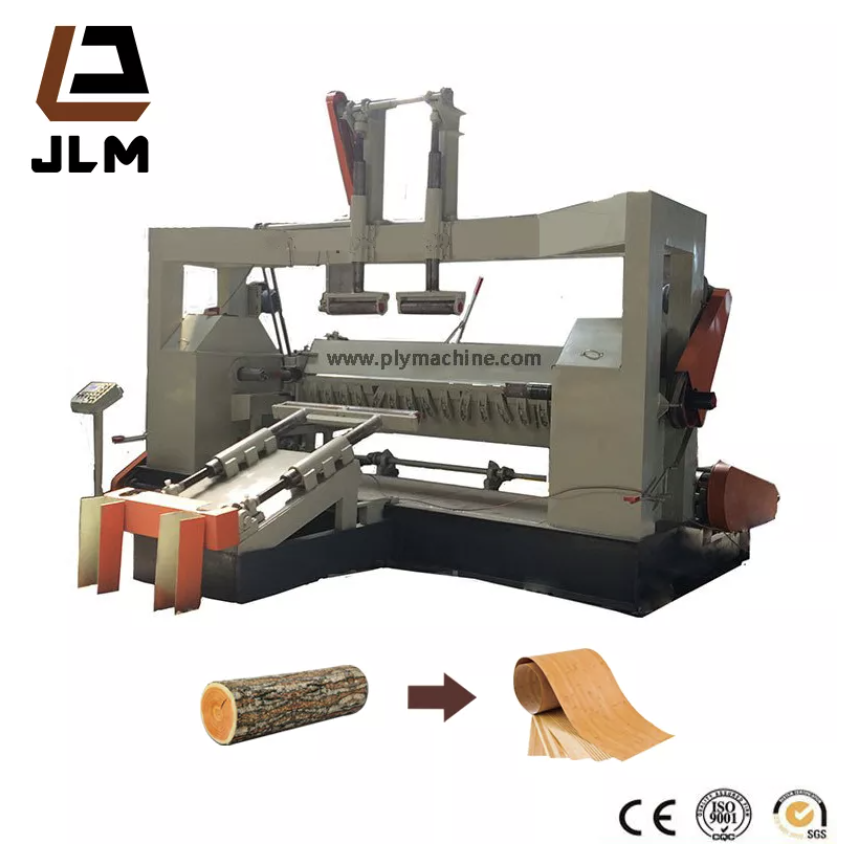

Shandong Jinlun Machinery manufacture limited company offers advanced debarker machines that deliver fast and efficient bark removal. These machines improve wood quality, protect equipment, and reduce labor costs.

Their industrial and portable models provide scalable solutions for any production need, ensuring long-term value and operational efficiency.

A: A debarker machine removes bark from logs efficiently, improving wood quality and protecting saw blades.

A: Common types include drum log debarkers, ring type debarkers, and portable debarker tools for small operations.

A: Industrial debarker machines handle high volumes, reduce labor costs, and ensure consistent bark removal.

A: Yes, portable debarker tools are lightweight, cost-effective, and ideal for small-scale or occasional work.

A: Regularly replace chains or blades and follow manufacturer guidelines to prevent downtime and maintain efficiency.