E-mail: info@plymachine.com WhatsApp:+8619553901259

Views: 0 Author: Site Editor Publish Time: 2025-09-25 Origin: Site

Have you ever wondered how logs are stripped before milling? The answer lies in the tree debarker. These machines come in several types, each designed for specific needs. In this article, you will learn about the main types of debarkers, their features, and where they work best.

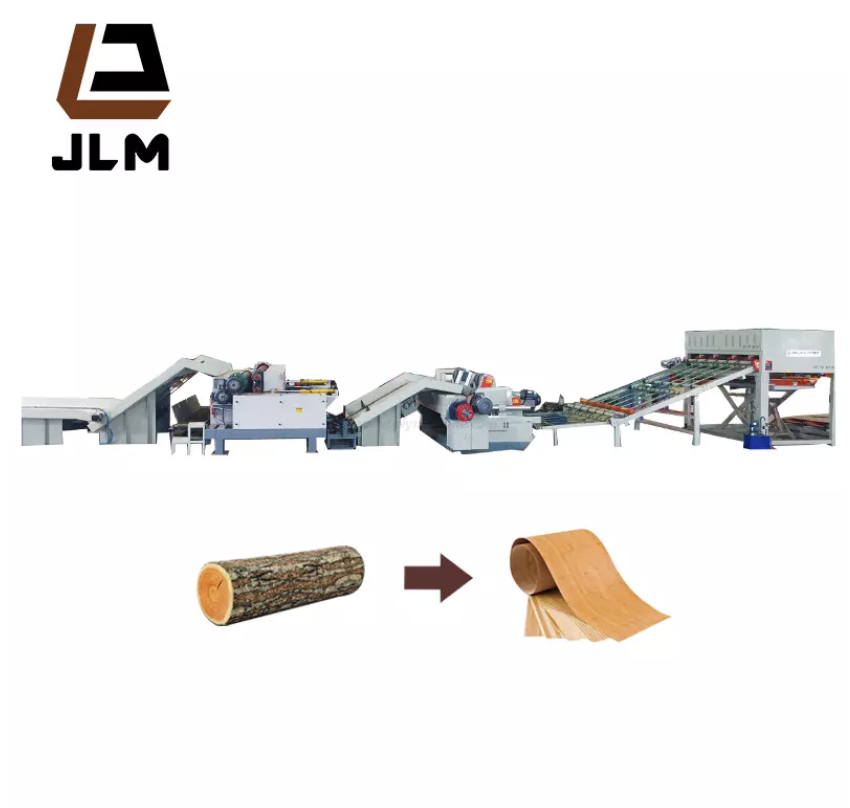

A tree debarker is a machine or tool designed to strip bark from logs. Bark removal is a critical step before logs enter sawmills, pulp mills, or furniture factories. Bark often contains dirt, grit, and insects that can reduce wood quality or damage cutting tools. Removing it ensures only clean wood enters the production line.

In small-scale or craft woodworking, hand tools like drawknives or bark spuds are still used. These are cost-effective but labor-intensive. An industrial log debarker machine, by contrast, processes hundreds of logs per shift, saving time and labor.

Bark left on logs can cause staining, uneven surfaces, or contamination. In sawmills, it dulls blades. In pulp production, it reduces fiber quality. Clean logs improve final product quality, reduce waste, and increase profit margins.

提示: Businesses that prioritize quality from the start gain long-term efficiency and higher customer satisfaction.

A drum log debarker processes multiple logs simultaneously, drastically reducing time compared to manual bark stripping. This efficiency lowers labor costs and increases daily output.

Consistency matters in industries like paper or construction. Machines such as a ring type debarker machine produce uniform results regardless of log size. This ensures predictability and reduces downstream rework.

Bark often hides moisture, insects, and imperfections. Using a chain log debarker system guarantees that bark is removed completely, leaving smooth surfaces. Cleaner logs mean higher lumber recovery rates.

Although industrial log debarker machines require investment, they reduce tool maintenance, labor, and wasted wood. The return on investment (ROI) comes from consistent efficiency and reduced downtime.

注释: A debarker is more than a tool—it’s a productivity multiplier that safeguards wood quality and boosts profits.

Type of Tree Debarker | How It Works | Best Application | Advantages | Disadvantages |

Drum Log Debarker | Logs tumble in a rotating drum; bark removed by friction | Pulp mills, mixed log batches | High volume, durable | Higher energy use |

Ring Type Debarker Machine | Rotating ring with knives strips bark | Sawmills, uniform logs | Precision, consistent | Less effective on irregular logs |

Chain Log Debarker System | Chains scrape bark as logs move through | Rough-barked logs | Effective on uneven logs | More wear and tear |

Portable Tree Debarker Tool | Manual or handheld powered device | Small-scale projects | Affordable, mobile | Slower, limited use |

Modern debarkers let operators adjust pressure, speed, and depth. For example, hardwood logs may need more pressure than softwoods. Adjustable settings ensure bark is removed efficiently without damaging valuable timber.

Blades, chains, and drums wear over time. Machines with easy-to-replace components save businesses downtime. Preventive maintenance schedules extend lifespan and ensure reliability.

Some industrial log debarker machines are designed for lower energy use, helping reduce operational costs while maintaining performance. This makes them attractive for businesses aiming to reduce environmental impact.

提示: When selecting features, always consider not just present needs but future expansion plans.

In sawmills, efficiency and precision directly affect profitability. Every cut made by a saw blade should produce usable, uniform boards with minimal waste. However, when bark or debris is left on logs, blades dull more quickly, leading to frequent sharpening or costly replacements. This is where a ring type debarker machine proves invaluable. By stripping bark from each log before it enters the sawing line, the debarker ensures that saws operate at peak performance. Clean logs result in smoother cuts, reduced wear on machinery, and greater consistency across final products. Additionally, debarked logs minimize the risk of introducing grit, stones, or insects into the sawmill process, protecting both equipment and product quality. In high-volume sawmill operations, the ability to process logs quickly and uniformly provides a strong competitive advantage. Over time, investing in the right tree debarker reduces downtime, increases yield, and helps sawmills deliver higher-quality boards that meet strict industry standards.

Pulp and paper mills demand raw materials that are as clean as possible. Bark, dirt, and other impurities reduce fiber quality, darken pulp color, and increase the amount of chemicals needed for processing. This not only affects the brightness and texture of the final paper but also drives up production costs. A drum log debarker is the preferred choice in this sector due to its ability to process large volumes and mixed sizes of logs efficiently. The rotating drum scrapes bark thoroughly while handling logs in bulk, which is critical for industries that process thousands of logs daily. Cleaner logs directly improve pulp brightness, reduce chemical bleaching requirements, and enhance overall fiber yield. For companies aiming to meet strict environmental regulations and lower operating costs, drum debarkers provide both ecological and economic benefits. In fact, studies [需要验证] suggest that mills using drum debarkers see a measurable reduction in chemical consumption, contributing to greener production.

The furniture industry thrives on aesthetics, where even the smallest imperfection can reduce a product’s market value. Rough bark remnants, discoloration, or uneven textures can compromise wood intended for high-end furniture, cabinetry, or specialty beams. For these applications, a chain log debarker system is often the best solution. Its scraping action adapts well to logs with irregular or rough bark, producing smooth, clean surfaces that are ideal for fine woodworking. Furniture makers and specialty wood product manufacturers rely on consistent, defect-free logs to ensure a flawless finish. Beyond aesthetics, debarking also prevents hidden damage such as insect infestation or rot, which might otherwise compromise wood strength. By investing in the right tree debarker, workshops can minimize material waste, lower rejection rates, and produce premium-quality wood that commands higher prices in the market. For artisanal woodworkers and niche producers, the precision offered by chain systems can be the difference between mediocre and exceptional craftsmanship.

Not every operation requires large-scale industrial systems. Farmers, small workshops, or mobile contractors often process logs in limited volumes for specific projects such as fencing, firewood preparation, or small construction jobs. In these cases, a portable tree debarker tool is the most practical option. These lightweight tools are cost-effective, easy to transport, and simple to operate, making them suitable for occasional or seasonal use. Unlike industrial debarkers, portable models don’t require complex installation or high energy consumption, which keeps overhead costs low. For rural users, the ability to debark logs on-site without hauling them to a centralized facility is a significant advantage. While portable tools cannot match the speed or consistency of industrial machines, they provide flexibility and convenience at a fraction of the cost. For small businesses or individual users, this balance of affordability and functionality makes portable debarkers an essential tool for low-volume wood processing.

One of the first considerations when selecting a tree debarker is production volume. High-output industries such as pulp mills, large sawmills, or industrial timber operations require the efficiency and durability of an industrial log debarker machine. These systems are designed to process hundreds or even thousands of logs daily, ensuring smooth operation without bottlenecks. By contrast, small producers, hobby sawyers, or niche furniture makers often benefit more from a portable tree debarker tool. These tools are compact, affordable, and easy to handle, but they are best suited for limited use. Choosing the wrong scale can lead to two major risks: underinvestment, which slows production and leaves businesses unable to meet demand; or overinvestment, where expensive equipment is underutilized and ties up capital. A practical step is to measure your current output, estimate future growth, and match a debarker to those figures. For example, if your shop processes fewer than 50 logs per day, a portable or small chain-based debarker may suffice, while a sawmill handling hundreds of logs requires an industrial-scale system.

Not all logs are created equal, and neither are their bark structures. Different species require different approaches. Softwood logs, such as pine or spruce, tend to have thinner and more uniform bark, making them suitable for a ring type debarker machine, which offers precision and consistency. On the other hand, hardwood logs like oak or hickory often have thick, rough, and uneven bark. In such cases, a chain log debarker system is far more effective, as its scraping action adapts to irregular surfaces. Another consideration is whether the bark carries high moisture or insect infestations, which can make removal more difficult. Operators should also assess whether they handle mixed species. For example, pulp mills dealing with both hardwood and softwood often favor a drum log debarker, which can manage mixed loads efficiently. Understanding your log mix prevents equipment mismatches and ensures maximum efficiency. Businesses that overlook this factor often face inconsistent results, higher wood damage, or wasted processing time.

Cost is a major factor, but focusing only on upfront price can be misleading. A drum log debarker requires a larger initial investment, but its speed and efficiency quickly generate a return on investment (ROI), especially for large-scale industries. On the other hand, a portable tree debarker tool comes at a fraction of the price, making it attractive for startups or small workshops. However, its slower processing speed limits its ROI in higher-volume settings. To make the smartest choice, companies should calculate cost per processed log rather than relying on purchase price alone. This method accounts for labor, downtime, energy use, and long-term productivity. For example, while a $100,000 machine may seem expensive, if it processes thousands of logs per month with minimal downtime, the payback period could be less than two years. Conversely, a cheaper tool may save money upfront but slow operations and reduce profitability. When evaluated over the full life cycle, higher investment often translates into greater efficiency and long-term savings.

The long-term success of a tree debarker doesn’t stop with its purchase—it also depends on maintenance and operating costs. Machines with complex mechanisms may deliver high efficiency but require frequent servicing, leading to downtime and increased expenses. For example, chain log debarker systems experience wear-and-tear on chains and guides, which need replacement after heavy use. Similarly, ring debarkers must have their blades kept sharp to maintain precision. Therefore, buyers should ask: How easy is it to replace parts? How often does the machine need servicing? Are replacement parts readily available? Choosing equipment with modular, user-friendly designs can reduce downtime significantly. Operators should also account for energy consumption. High-energy machines, like drum debarkers, may drive up utility costs unless designed with energy-efficient features. Companies that underestimate operating expenses often face hidden costs that undermine ROI. A well-maintained debarker not only lasts longer but also delivers consistent performance, ensuring logs are processed cleanly and reliably.

A crucial factor often overlooked is scalability. Many small businesses eventually grow, and choosing a tree debarker that cannot handle increased demand leads to reinvestment sooner than expected. An industrial log debarker machine is typically scalable, designed to manage larger volumes as operations expand. Smaller or portable models, while useful, may not adapt well to growth, forcing a business to buy new equipment in just a few years. For example, a sawmill starting with 100 logs per day may expand to 300 logs within five years. If the original debarker can’t handle that increase, productivity stalls and customer demand may not be met. It’s also worth considering whether the machine can handle diverse log types, as expanding operations often introduce new species or sizes. Investing in a debarker with adjustable settings or modular upgrades helps future-proof your business. Companies that plan ahead avoid costly reinvestments and position themselves for smoother scaling as demand grows.

Debarker Type | Best For | Pros | Cons |

Drum Log Debarker | High-volume pulp mills | Handles mixed logs, durable | Energy-intensive |

Ring Type Debarker | Sawmills, uniform logs | Precision, consistency | Limited flexibility |

Chain Log Debarker | Rough or irregular bark | Works on tough surfaces | Higher wear rate |

Portable Tree Debarker Tool | Small-scale projects | Affordable, easy to use | Low capacity |

注释: No single debarker fits all needs; the right choice depends on operation size, wood type, and production goals.

Shandong Jinlun Machinery manufacture limited company offers advanced tree debarker machines for all scales. Their equipment provides high efficiency, consistent debarking, and minimal wood waste. From industrial log debarker machines to portable tools, they meet diverse industry needs. Choosing their tree debarking solutions ensures quality, reliability, and long-term value for sawmills, pulp mills, and woodworking operations.

A: A tree debarker removes bark efficiently from logs using machines like drum log debarker or chain log debarker system.

A: Common types include ring type debarker machine, drum log debarker, chain log debarker system, and portable tree debarker tool.

A: Consider log size, bark type, production volume, and budget. Industrial log debarker machines suit high-output mills.

A: A tree debarker saves time, reduces labor, ensures consistent debarking, and improves wood quality.

A: Yes, they are ideal for small-scale or mobile operations and occasional wood processing tasks.

A: Drum log debarkers handle high volumes, mixed log sizes, and provide smooth, clean logs for pulp and sawmills.