E-mail: info@plymachine.com WhatsApp:+8619553901259

| Availability: | |

|---|---|

| Quantity: | |

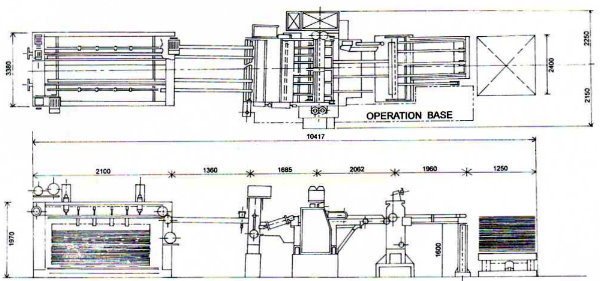

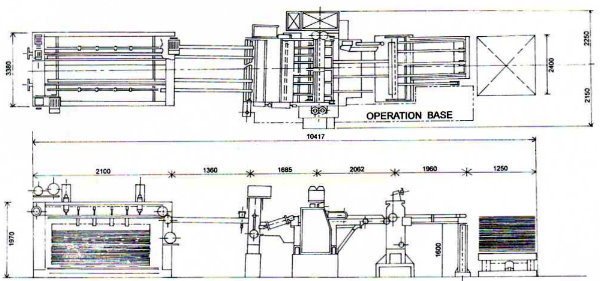

By integrating automated processes such as width detection, thickness sorting, hole inspection, edge trimming, glue application, jointing, sizing, and stacking, it eliminates the need for manual, labor-intensive steps. This not only reduces material waste but also significantly improves veneer quality and production efficiency, making it an indispensable tool for modern woodworking facilities aiming to streamline operations and cut costs.

Advanced Automation & Labor Savings: Equipped with a PLC computer control system, the machine operates with minimal human intervention—requiring just 1 worker to oversee the entire process. This automation reduces labor costs by 70% for veneer repair, 80% for veneer forming, and 50% for puttying, delivering substantial long-term savings.

High Precision Performance: Boasts high-precision detection technology that ensures accurate cutting even for small-sized veneers, minimizing material loss. The integration of servo control guarantees precise positioning, effectively reducing overlap seams and enhancing the uniformity of joined veneers.

Durable & Reliable Components: To ensure longevity and consistent performance, the machine uses components from international renowned brands, including Germany’s Festo, Taiwan’s Delta, Germany’s Siemens, Japan’s Mitsubishi, Taiwan’s TECO, and Germany’s NSK. This quality build reduces downtime and maintenance needs.

Strong Adhesion & Veneer Integrity: Utilizes dedicated high-strength hot-melt glue threads to secure joints, preventing veneer breakage during and after processing. This ensures the joined sheets maintain structural stability in subsequent manufacturing steps.

Impressive Speed & Versatility: With a jointing speed of 60m/min and a jointing thickness range of 0.9mm–10mm, it accommodates a wide variety of veneer types, making it suitable for diverse production demands.

Parameter | Specification |

Jointing Speed | 60m/min |

Jointing Thickness | 0.9mm–10mm |

Control System | PLC computer control |

Key Component Brands | Festo (Germany), Siemens (Germany), Mitsubishi (Japan), etc. |

Labor Requirement | 1 worker |

Labor Cost Savings | 70% (repair), 80% (forming), 50% (puttying) |

The plywood veneer composer is versatile enough to serve multiple woodworking sectors, including:

Plywood Manufacturing: Efficiently joins core veneers to produce high-quality plywood sheets used in construction, packaging, and furniture.

Floorboard Production: Creates uniform base materials for floorboards, ensuring consistency in thickness and strength.

Furniture Industry: Processes veneers for furniture panels, reducing defects and improving the aesthetic appeal of final products.

Building Materials: Manufactures veneers for building templates, container plates, and melamine ecological boards, meeting strict industry standards.

Block Board Production: Optimizes the core structure of block boards, enhancing their durability and performance.

It is designed for dry veneers, including those with irregular lengths, non-uniform thicknesses, and both regular and irregular shapes. This flexibility makes it ideal for handling leftover or off-cut veneers that would otherwise go to waste.

By automating key steps—from detection to stacking—it eliminates manual delays. With a 60m/min jointing speed, it outperforms traditional methods, increasing daily output significantly.

No. The use of international brand components (e.g., Siemens, Mitsubishi) ensures reliability and ease of maintenance. Shandong Jinlun Machinery also provides detailed maintenance guides and responsive after-sales support.

Yes. Depending on factors like veneer size range and output requirements, the machine can be adjusted to fit unique production lines. The technical team works closely with clients to tailor solutions.

Absolutely. Shandong Jinlun Machinery provides on-site training for operators, covering setup, operation, and basic troubleshooting to ensure optimal use of the equipment.

By integrating automated processes such as width detection, thickness sorting, hole inspection, edge trimming, glue application, jointing, sizing, and stacking, it eliminates the need for manual, labor-intensive steps. This not only reduces material waste but also significantly improves veneer quality and production efficiency, making it an indispensable tool for modern woodworking facilities aiming to streamline operations and cut costs.

Advanced Automation & Labor Savings: Equipped with a PLC computer control system, the machine operates with minimal human intervention—requiring just 1 worker to oversee the entire process. This automation reduces labor costs by 70% for veneer repair, 80% for veneer forming, and 50% for puttying, delivering substantial long-term savings.

High Precision Performance: Boasts high-precision detection technology that ensures accurate cutting even for small-sized veneers, minimizing material loss. The integration of servo control guarantees precise positioning, effectively reducing overlap seams and enhancing the uniformity of joined veneers.

Durable & Reliable Components: To ensure longevity and consistent performance, the machine uses components from international renowned brands, including Germany’s Festo, Taiwan’s Delta, Germany’s Siemens, Japan’s Mitsubishi, Taiwan’s TECO, and Germany’s NSK. This quality build reduces downtime and maintenance needs.

Strong Adhesion & Veneer Integrity: Utilizes dedicated high-strength hot-melt glue threads to secure joints, preventing veneer breakage during and after processing. This ensures the joined sheets maintain structural stability in subsequent manufacturing steps.

Impressive Speed & Versatility: With a jointing speed of 60m/min and a jointing thickness range of 0.9mm–10mm, it accommodates a wide variety of veneer types, making it suitable for diverse production demands.

Parameter | Specification |

Jointing Speed | 60m/min |

Jointing Thickness | 0.9mm–10mm |

Control System | PLC computer control |

Key Component Brands | Festo (Germany), Siemens (Germany), Mitsubishi (Japan), etc. |

Labor Requirement | 1 worker |

Labor Cost Savings | 70% (repair), 80% (forming), 50% (puttying) |

The plywood veneer composer is versatile enough to serve multiple woodworking sectors, including:

Plywood Manufacturing: Efficiently joins core veneers to produce high-quality plywood sheets used in construction, packaging, and furniture.

Floorboard Production: Creates uniform base materials for floorboards, ensuring consistency in thickness and strength.

Furniture Industry: Processes veneers for furniture panels, reducing defects and improving the aesthetic appeal of final products.

Building Materials: Manufactures veneers for building templates, container plates, and melamine ecological boards, meeting strict industry standards.

Block Board Production: Optimizes the core structure of block boards, enhancing their durability and performance.

It is designed for dry veneers, including those with irregular lengths, non-uniform thicknesses, and both regular and irregular shapes. This flexibility makes it ideal for handling leftover or off-cut veneers that would otherwise go to waste.

By automating key steps—from detection to stacking—it eliminates manual delays. With a 60m/min jointing speed, it outperforms traditional methods, increasing daily output significantly.

No. The use of international brand components (e.g., Siemens, Mitsubishi) ensures reliability and ease of maintenance. Shandong Jinlun Machinery also provides detailed maintenance guides and responsive after-sales support.

Yes. Depending on factors like veneer size range and output requirements, the machine can be adjusted to fit unique production lines. The technical team works closely with clients to tailor solutions.

Absolutely. Shandong Jinlun Machinery provides on-site training for operators, covering setup, operation, and basic troubleshooting to ensure optimal use of the equipment.