E-mail: info@plymachine.com WhatsApp:+8619553901259

As a standout product in the Veneer Peeling Line under the Knife Grinder category, the Knife Grinding Machine and Blade Sharpener for The Wood Chipper is proudly crafted by Shandong Jinlun Machinery Manufacturing Co., Ltd., a company with 27 years of industry expertise.

| Availability: | |

|---|---|

| Quantity: | |

Adhering to the philosophy of "quality based on the market, innovation-driven development, and customer satisfaction service", we ensure this machine meets the highest standards. This machine is designed to provide high-precision grinding for blades used in wood chippers, playing a crucial role in enhancing the efficiency and quality of wood processing operations. Its robust construction and advanced features make it a reliable choice for various woodworking applications.

Parameter | LMD-MZ7135 | LMD-MZ7130 | LMD-MZ7120 | LMD-MZ7115 |

Max. grinding length | 3600 mm | 3200 mm | 2200 mm | 1600 mm |

Working-table width | 3350x180(200) mm | 3000x180(200) mm | 2270x180(200) mm | 550x180(200) mm |

Wheel size(diameter) | 200x100x32 mm | 200x100x32 mm | 200x100x32 mm | 200x100x32 mm |

Working voltage | 380 V | 380 V | 380 V | 380 V |

Overall dimensions | 5800x1300x1300 mm | 5200x1300x1300 mm | 4250x1300x1300 mm | 3850x1300x1300 mm |

Grinding wheel reciprocating speed | About 17 m/min | About 17 m/min | About 17 m/min | About 17 m/min |

Work tool with adjustable angle | ±90 ° | ±90 ° | ±90 ° | ±90 ° |

Grinding head driving mode | Transmission(optional frequency dynamic) | Transmission(optional frequency dynamic) | Transmission(optional frequency dynamic) | Transmission(optional frequency dynamic) |

Total power | About 6 KW | About 6 KW | About 6 KW | About 6 KW |

Total weight | About 3200 KG | About 2800 KG | About 2000 KG | About 1800 KG |

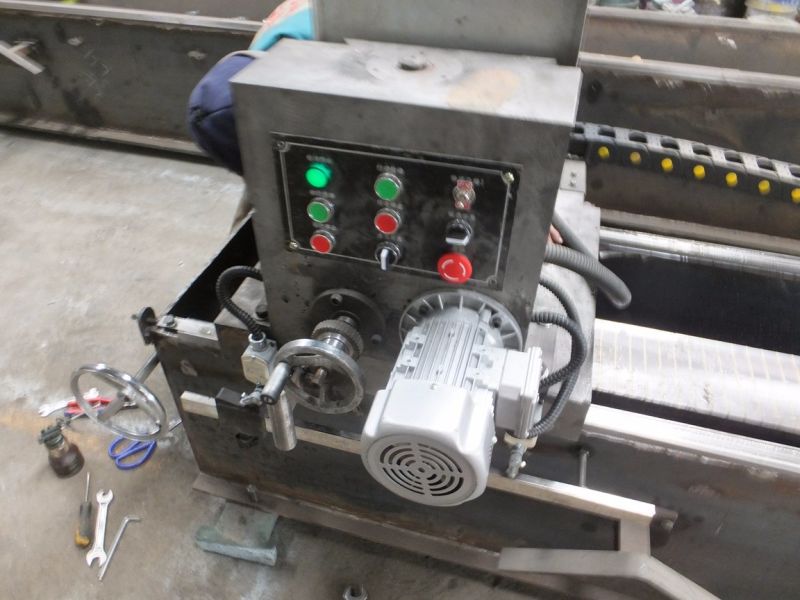

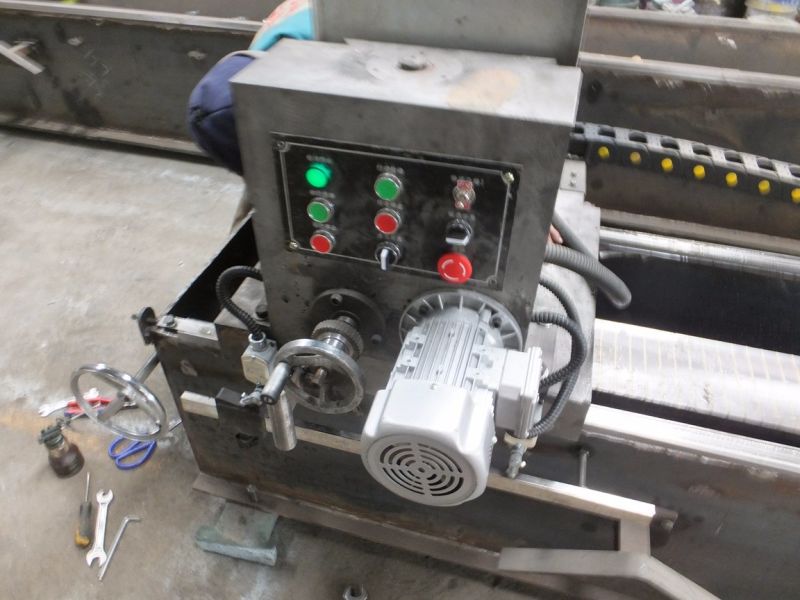

The machine's side bed is constructed with national standard double steel liner reinforced floors and thick plate welding. Through special treatment, it fully guarantees the stability of the entire machine, ensuring no vibration and no deformation during operation. The walking part is made of cast iron casting, which is processed to be non-deformable, further enhancing the overall stability.

The machine's running system utilizes a precision gear reducer with gear and rack, combined with a frequency converter. This configuration achieves stable operation and walking, significantly improving grinding quality and efficiency. The rational design of the GB special grinding machine grinding head motor ensures precision grinding, stronger suction, and extends the service life of the machine.

The machine head part is equipped with a fast lifting device, making the replacement of the grinding wheel more convenient and efficient. This not only improves work efficiency but also reduces labor intensity for operators, making daily use and maintenance much easier.

Special design according to customer requirements is available. We understand that different customers may have unique needs in their wood processing operations, and our ability to customize ensures that the machine can perfectly fit various working scenarios.

The Knife Grinding Machine and Blade Sharpener for The Wood Chipper is widely applied in the wood processing industry. It is mainly used for sharpening the blades of wood chippers, which are essential equipment in plywood production lines, veneer peeling lines, and other wood processing processes. By ensuring the sharpness of the blades, this machine helps to improve the quality of wood chips, veneers, and plywood, thereby enhancing the overall production efficiency of wood processing enterprises. It is suitable for small, medium, and large wood processing factories that require high-precision blade grinding.

We provide a warranty period of 12 months from the date of delivery. During this period, we will offer free repair or replacement of parts that have quality problems under normal use.

Yes, we offer installation and debugging services. Our professional technicians can be dispatched to the customer's site to guide the installation, conduct debugging, and train the operators on how to use the machine properly.

While the machine is primarily designed for grinding blades used in wood chippers, it can also be used for grinding blades of similar materials and specifications, provided that the blades are compatible with the machine's parameters. It is recommended to consult our technical team before using it for other types of blades.

The replacement cycle of the grinding wheel depends on the frequency of use and the hardness of the blades being ground. Under normal working conditions, the grinding wheel can last for about 3-6 months. Regular inspection of the grinding wheel's wear condition is advisable to ensure grinding quality.

The delivery time is usually 30-45 days after receiving the advance payment. However, it may be affected by factors such as order quantity and customization requirements. We will communicate the specific delivery time with customers in advance.

Adhering to the philosophy of "quality based on the market, innovation-driven development, and customer satisfaction service", we ensure this machine meets the highest standards. This machine is designed to provide high-precision grinding for blades used in wood chippers, playing a crucial role in enhancing the efficiency and quality of wood processing operations. Its robust construction and advanced features make it a reliable choice for various woodworking applications.

Parameter | LMD-MZ7135 | LMD-MZ7130 | LMD-MZ7120 | LMD-MZ7115 |

Max. grinding length | 3600 mm | 3200 mm | 2200 mm | 1600 mm |

Working-table width | 3350x180(200) mm | 3000x180(200) mm | 2270x180(200) mm | 550x180(200) mm |

Wheel size(diameter) | 200x100x32 mm | 200x100x32 mm | 200x100x32 mm | 200x100x32 mm |

Working voltage | 380 V | 380 V | 380 V | 380 V |

Overall dimensions | 5800x1300x1300 mm | 5200x1300x1300 mm | 4250x1300x1300 mm | 3850x1300x1300 mm |

Grinding wheel reciprocating speed | About 17 m/min | About 17 m/min | About 17 m/min | About 17 m/min |

Work tool with adjustable angle | ±90 ° | ±90 ° | ±90 ° | ±90 ° |

Grinding head driving mode | Transmission(optional frequency dynamic) | Transmission(optional frequency dynamic) | Transmission(optional frequency dynamic) | Transmission(optional frequency dynamic) |

Total power | About 6 KW | About 6 KW | About 6 KW | About 6 KW |

Total weight | About 3200 KG | About 2800 KG | About 2000 KG | About 1800 KG |

The machine's side bed is constructed with national standard double steel liner reinforced floors and thick plate welding. Through special treatment, it fully guarantees the stability of the entire machine, ensuring no vibration and no deformation during operation. The walking part is made of cast iron casting, which is processed to be non-deformable, further enhancing the overall stability.

The machine's running system utilizes a precision gear reducer with gear and rack, combined with a frequency converter. This configuration achieves stable operation and walking, significantly improving grinding quality and efficiency. The rational design of the GB special grinding machine grinding head motor ensures precision grinding, stronger suction, and extends the service life of the machine.

The machine head part is equipped with a fast lifting device, making the replacement of the grinding wheel more convenient and efficient. This not only improves work efficiency but also reduces labor intensity for operators, making daily use and maintenance much easier.

Special design according to customer requirements is available. We understand that different customers may have unique needs in their wood processing operations, and our ability to customize ensures that the machine can perfectly fit various working scenarios.

The Knife Grinding Machine and Blade Sharpener for The Wood Chipper is widely applied in the wood processing industry. It is mainly used for sharpening the blades of wood chippers, which are essential equipment in plywood production lines, veneer peeling lines, and other wood processing processes. By ensuring the sharpness of the blades, this machine helps to improve the quality of wood chips, veneers, and plywood, thereby enhancing the overall production efficiency of wood processing enterprises. It is suitable for small, medium, and large wood processing factories that require high-precision blade grinding.

We provide a warranty period of 12 months from the date of delivery. During this period, we will offer free repair or replacement of parts that have quality problems under normal use.

Yes, we offer installation and debugging services. Our professional technicians can be dispatched to the customer's site to guide the installation, conduct debugging, and train the operators on how to use the machine properly.

While the machine is primarily designed for grinding blades used in wood chippers, it can also be used for grinding blades of similar materials and specifications, provided that the blades are compatible with the machine's parameters. It is recommended to consult our technical team before using it for other types of blades.

The replacement cycle of the grinding wheel depends on the frequency of use and the hardness of the blades being ground. Under normal working conditions, the grinding wheel can last for about 3-6 months. Regular inspection of the grinding wheel's wear condition is advisable to ensure grinding quality.

The delivery time is usually 30-45 days after receiving the advance payment. However, it may be affected by factors such as order quantity and customization requirements. We will communicate the specific delivery time with customers in advance.