- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

ADDRESS

| Availability: | |

|---|---|

| Quantity: | |

plywood veneer composer/veneer finger jointer for sale

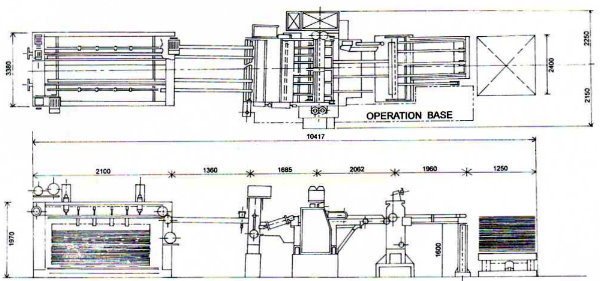

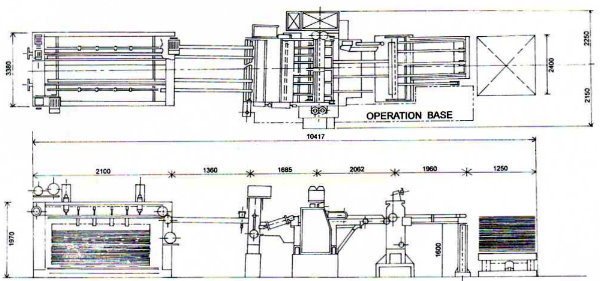

shandong jinlun machinery core veneer composer fit for plywood making,floor board material,furniture board, building templates, container plate, melamine ecological board,block board, etc.Cross-link of Peeled core veneer,it is to join core veneer uneven in length,irregular veneer,regular veneer and make these material into big whole veneer.This style improved the traditional veneer forming method,saved the cost of repairing veneer,upgraded the veneer quality, and increased the production efficiency.

Working Principles

This machine is for the dry veneer, which is uneven in length, non-uniform in thickness, irregular or regular. This machine will automatically do the width detecting, thickness separating, hole detecting, edge cutting, glue spreading and jointing, cutting to size, stacking, and make the whole core veneer as your needs.

Features Advantages

01. PLC computer control, one worker operation, automatic process, labor cost saving

02. High precision detecting, cutting size in minimum.

03. Servo control makes it precise location and effectively control the overlap seam.

04. Use dedicated high-strength heat melts glue thread to stop the veneer breaking.

05. We use international famous brand parts such as Germany Festo, Taiwan Delta, Germany 0Siemens, Japan Mitsubishi, Taiwan TECO, Germany NSK,etc.

06. Saving 70% worker cost of veneer repairing

07. Saving 80% worker cost of veneer forming

08. Saving 50% worker cost of puttying

09. Jointing speed: 60m/min

10. Jointing Thickness: 0.9mm-10mm

plywood veneer composer/veneer finger jointer for sale

shandong jinlun machinery core veneer composer fit for plywood making,floor board material,furniture board, building templates, container plate, melamine ecological board,block board, etc.Cross-link of Peeled core veneer,it is to join core veneer uneven in length,irregular veneer,regular veneer and make these material into big whole veneer.This style improved the traditional veneer forming method,saved the cost of repairing veneer,upgraded the veneer quality, and increased the production efficiency.

Working Principles

This machine is for the dry veneer, which is uneven in length, non-uniform in thickness, irregular or regular. This machine will automatically do the width detecting, thickness separating, hole detecting, edge cutting, glue spreading and jointing, cutting to size, stacking, and make the whole core veneer as your needs.

Features Advantages

01. PLC computer control, one worker operation, automatic process, labor cost saving

02. High precision detecting, cutting size in minimum.

03. Servo control makes it precise location and effectively control the overlap seam.

04. Use dedicated high-strength heat melts glue thread to stop the veneer breaking.

05. We use international famous brand parts such as Germany Festo, Taiwan Delta, Germany 0Siemens, Japan Mitsubishi, Taiwan TECO, Germany NSK,etc.

06. Saving 70% worker cost of veneer repairing

07. Saving 80% worker cost of veneer forming

08. Saving 50% worker cost of puttying

09. Jointing speed: 60m/min

10. Jointing Thickness: 0.9mm-10mm